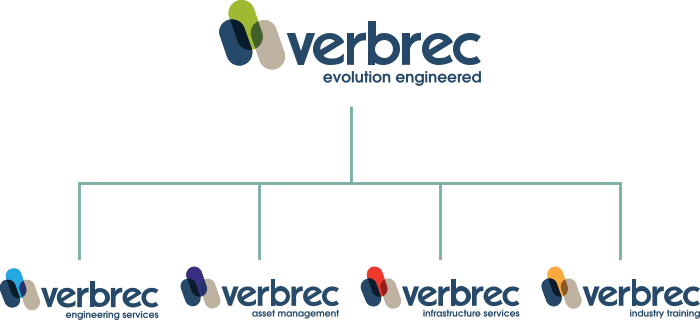

Engineering

Verbrec Engineering services provide innovative engineering and project delivery solutions to clients – through our technical specialties, including Automation & control, Power, Process plant, Pipelines and Asset management.

Asset Management

Verbrec Asset Management specialises in working with owners and operators across Australia, New Zealand and PNG to provide asset management solutions that increase efficiencies, reduce cost and improve productivity, unlocking higher value from client’s assets.

Infrastructure

Verbrec Infrastructure provides clients full lifecycle services for project delivery from inception through procurement and/or construction, commissioning, and operations. We have positioned ourselves in the market to be agile and responsive to clients’ needs, providing innovative and cost-efficient solutions to Australia’s infrastructure operators.

Industry Training

Verbrec Industry Training through the trade name, Competency Training delivers a range of hazardous areas, high voltage, safety, access courses, and qualifications to help you or your employees advance in the mining, resources, oil, gas, construction, and engineering industries.

Evolution Engineered

Under our new name, we have brought together Australian and New Zealand companies with over 30 years of experience providing engineering and operations services to the mining, energy, and infrastructure sectors.

Verbrec offers our clients a better way of working, with high performance, a relentless safety focus, and an accountable people-focused culture

Process Plant

Outstanding service delivery across all disciplines.

Verbrec provides multi-disciplinary and single-discipline engineering and project delivery services for the oil and gas, chemicals, mining and minerals, water, power, sugar, and food & beverage industries.

- Capex and Opex

- Design and Drafting Services

- Civil & Structural Engineering and Design

- Electrical & Instrumentation and Controls & Automation Engineering

- Broad Engineering and Project Delivery Capability

- Mechanical and Piping Engineering

- Process Engineering

Asset Management

Unlock higher value from your assets.

Working with asset owners and operators across Australia, New Zealand, and Papua New Guinea, the Verbrec Asset Management team provides solutions that drive efficiency gains, cost reductions, productivity improvements to unlock higher value from client assets.

- Plant Shutdowns & Turnarounds

- Operational Readiness

- Data Science & Master Data

- Materials & Inventory

- Specialist Asset Management Training

- Performance Consulting

- Maintenance & Reliability Engineering

- Asset Integrity

Pipelines

Excellence in the whole of life pipeline services.

As pipeline industry leaders, we have been involved in the successful installation of thousands of kilometres of oil, gas, water, and slurry pipelines throughout Australia, New Zealand, Papua New Guinea, the Pacific Islands, and South America.

- Geospatial Data Management

- Inspection & Field Services

- Cathodic Protection Services

- Procurement & Construction

- Integrity Management

- Engineering & Design

- Regulatory Compliance

Power

We add value at every stage of your power project.

We provide our clients with secure, cost-effective and robust electrical and instrumentation system solutions that are code compliant and tailored to your requirements.

- Electrical Distribution Infrastructure and Plant Instrumentation Design

- Design of Earthing, Lightning Protection & Electrostatic Control

- Regulatory Services

- Plant Instrumentation Design (inc. Functional & Machine Safety)

- Hazardous Areas Classification

- High Voltage Distribution Infrastructure

- Electrical Power System Modelling

Automation & Control

Control systems, automation and Industrial data management.

We have extensive systems integration experience and data management expertise. This provides our clients fit for purpose control and monitoring functionality that collects, manages and utilises data to optimise production and enable predictive management of assets.

- Digital Industry Consulting

- Data Management, Analysis and Utilisation

- Seamless Delivery

- Industrial Networks and IT Infrastructure

- Operational Technology (Control and Automation)

- INDUSTRY 4.0 - Capturing the Power of Your Data

- Leading Digital Industry Capability

- Greenfield and Brownfield Experience

Maintenance & Operations

Verbrec’s 29-year investment in the development of Engineering, Project Execution, Operations and Maintenance capability to support the performance of its assets is on offer to the external market as an integrated services offering.

This service model has seen Verbrec emerge as a class-leading midsized energy infrastructure services provider with a strong positive financial position that operates with tier-1 systems but is lean, flexible, and fast to act.

- Responsible for full compliance under P&G Act 2004 QLD

- Preventative and Reactive Maintenance

- Maintenance Management (CMMS)

- Regulatory Reporting

- 24/7 Breakdown and Emergency Response Services

- Dial Before You Dig (DBYD)

Industry Training

Verbrec under the trade names, Competency Training (CT) and Site Skills Training (SST) delivers a range of hazardous areas, high voltage and high-risk training courses.

Site Skills Training and Competency Training run weekly high-risk work licence courses and qualifications designed to help you or your employees advance in mining, resources, oil, gas, construction and engineering industries.

- High-risk work licences

- Certificate III & Certificate IV Qualifications

- Funded Training

- Accredited and Non-Accredited Training

- Verification of Competency

- Onsite Training

Industries

Energy

Verbrec’s deep experience in hydrocarbon-derived energy combined with our leading-edge experience in renewables and decarbonisation means that Verbrec is uniquely positioned to service the transition to net zero.

Mining

Verbrec has an exemplary track record of productivity improvement and innovation in the mining industry. From the pit to the port, we intimately understand the key commercial drivers in the value chain. This means our talented team and innovative solutions such as StacksOn™ integrate seamlessly with mining companies, regardless of size, to deliver safe, sustainable, cost-effective solutions that minimise risk and maximise throughput.

Infrastructure

Verbrec enjoys a depth of experience in infrastructure development and maintenance that can only be gained as a licensed operator. From design to project execution, commissioning and best practice asset management strategies, we know how to unlock the true potential of an asset.

We work with the best

Verbrec offers our clients a better way of working, with high performance, a relentless safety focus, and an accountable, people-focused culture.